BAND HEATERS

Nice Heaters is one of the growing brands in the industrial heater industry, you can contact us for buying an extensive range of band heaters. Being the noteworthy band heater manufacturers In Delhi, we use good quality standard raw materials that are procured from renowned suppliers. Our Band heaters are mostly used in injection moulding machine to heat barrel.

Being the noted Mica Band Heaters Suppliers and Exporters, we offer our complete range as per industrial application. So, what are you waiting for? Still, have some doubts or confusions in your mind? Let us sort them all, so, you can invest in a wise option that fulfills the need of your application.

Type of band heater as per client requirements are:

- Mica Band Heater - Nice heaters Mica band provides efficient and economical solutions for heating cylindrical surfaces of machines that require external indirect heating. Mica Band Heaters are most widely used band heater because of their all-round design and rugged construction characteristics. Mica Band heaters are constructed with a mica strip wounded with resistance wire. The strips are then bended into a circular band. Leads are attached before the final outer sheaths to complete the heater. The band heater withstands temporary temperatures up to 350°C. It has an even heat distribution. Mica band heaters can be provided with built in thermocouple and nipples, holes and slots for external temperature sensors. Power supply can be connected by pre-assembled cables, connection boxes or contacts. We design heater as per client requirement.

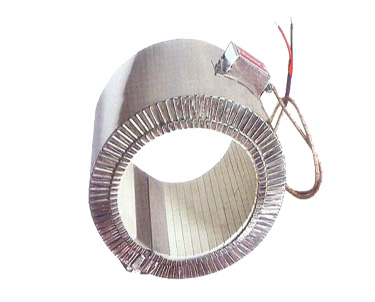

- Ceramic Band Heater - Ceramic Band Heaters are invented to meet industrial requirements of high temperature. They are designed to to comply with today's new resins, which demand ever-increasing process temperatures. It is used to heat large cylinders for intermediate to high temperatures of 1600°F (870°C) without concern of failures due to "Hot-Spotting" that conventional bands heaters are susceptible to when used on large diameter cylinders. Ceramic band heaters are designed with spirally wound inner resistance coils evenly threaded through interlocking insulated ceramic "tiles". The ceramic core, or "mat" of tiles is housed beneath a stainless steel sheet with serrated edges. We design heater as per client requirement.

- Power Saving Ceremic Band Heater - Specifically designed and engineered to meet the ever increasing demand for energy conservation and to improve operation efficiency capable of generating higher temperature essential to process today's high temperature resins. Nice heater's Energy Saving Ceramic Band Heater have ceramic band heater with 15mm or 25mm thick Ceramic fiber insulation blanket. We design heater as per client requirement.

- Aluminum Casted Band heater

Applications Of Band Heater

- Injection, Extrusion and Moulding Processes

- Plastic Processing Industry

- Chemical Industries

- Food Processing Industries

- Oil Lubricating Unit

- External Tank And Vessel Heating

- Blown Film Dies

- For melting plastic granules prior to molding

- Extrusion barrel & dies

- Blow molding

- Compounding

- Rubber machinery

Our Contact Us

- G-52, Lawrence Road Industrial Area, Delhi - 110035

- Mon-Sun 10:00 AM - 07:00 PM

- +91-965 043 7506